ADVERTISEMENT

However, beneath the layers of internet humor lies a sophisticated reality of textile engineering. To understand the line, one must first understand the anatomy of a towel. While we perceive a towel as a singular piece of fabric, it is actually a carefully constructed tool designed to balance three often-conflicting goals: extreme absorbency, structural durability, and aesthetic appeal.

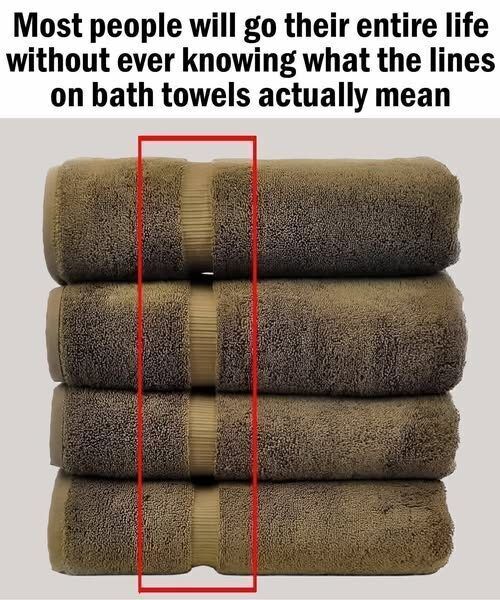

Textile professionals eventually stepped in to provide the definitive answer, introducing the public to a term most had never heard: the dobby border. Far from being a mere decorative flourish or a “butt-to-face” divider, the dobby border is a functional powerhouse. It is a specific weave—distinct from the “terry” loops that make up the rest of the towel—created using a dobby loom. This loom allows for the creation of small, geometric patterns and a tighter, flatter weave than the surrounding pile.

Furthermore, the dobby border addresses the challenge of bulk and weight. If a manufacturer were to simply make the edges of a towel thicker to prevent fraying, the towel would become unwieldy. It would take significantly longer to dry, and the heavy edges would make it difficult to hang neatly on a rack. The dobby border provides strength without adding unnecessary mass. By using a flatter, more compressed weave, manufacturers can ensure the towel remains lightweight and quick-drying while still being incredibly tough at its most vulnerable points.

Beyond the engineering, there is the undeniable element of practical aesthetics. In the world of hospitality—hotels, spas, and gyms—visual cues are essential. The dobby border provides a natural “fold line,” ensuring that staff can stack hundreds of towels with mathematical precision and symmetry. This creates the crisp, clean look we associate with luxury accommodations. For the home user, it provides a subtle touch of sophistication, transforming a basic utility item into a piece of “decor” that hangs straight and looks refined. It also provides a dedicated space for branding, where high-end designers can weave in subtle logos or jacquard patterns without compromising the absorbency of the main body of the towel.

ADVERTISEMENT